|

Ridecon can do Contracted Electronics Manufacturing or Full OEM Product Development

We have a strong engineering team that can follow up and trouble-shoot for the technical issues happen during production.

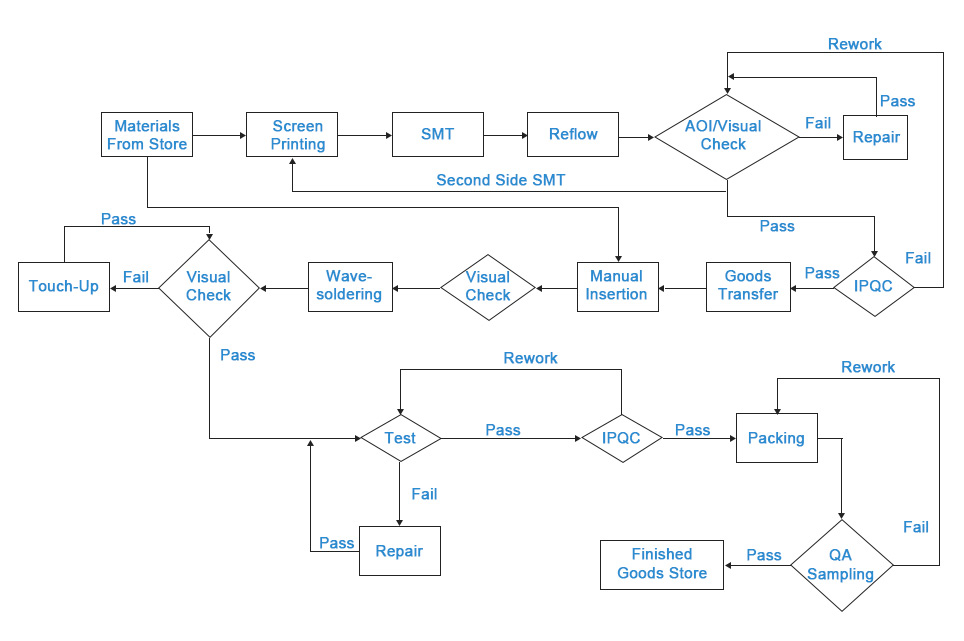

Electronics manufacturing Flow Chart:

|

PCB Assembly (Lead Free PCB Assembly,RoHS):

- Vision aligned solder paste deposition

- 0201 to uBGA SMT placement capability

- Pin In Paste (Intrusive Reflow)

- High velocity forced hot air reflow systems

- Light-guided work stations for conventional 'thru-hole' PCB assembly

- Latest dual wave, flow soldering equipment

- Programmable Selective Soldering

- Analogue, Digital, RF and Functional test development, operation and debug In house FPGA and EPROM programming

- Workmanship to IPC-610 class 3 or MIL STD 2000 equivalent

Final Product Assembly

- Assemble your printed circuit boards into finished product box assemblies

- Provide cabinet, rack and backplane wired assemblies

- Press-fit connectors into high density PCBs & Backplanes

- Provide in house FPGA and EPROM programming facilities

- Assemble complex cable forms & harnesses

- Carry out potting, encapsulation and heat shrinking

- Provide automated 'cut and strip' facilities to ensure accuracy of wire processing

- Carry out semi-automated wire wrapping of complex assemblies

- Provide service and repair facilities for product refurbishment and upgrade

- Provide Functionality Testing,

- Well package and storage and ready to ship

Quality Systems Includes :

IPQC,IQC, QA systems ,strict quality control for every components and working stage. From prototype to early production volume we report on:

- Production and value engineering to ensure suitability of components and repeatability of the manufacturing process

- Generation of manufacturing control documents

- Early prototype build and design analysis

- Design of test fixtures and software development

- Material traceability & documentation control

- Unique product serializations

|

|

|